Our Products

- Distribution Transformers

- Power Transformer

- Auto Recloser Circuit Breaker

- MV Overhead Switch with Break under SF6 (Auto Sectionaliser)

- Air-Insulated Modular Cell

- Fused Compact RMU cubicle (Shielded Cubicle)

- Withdrawable cell (Metal Clad Cell)

- Aluminum Alloy Conductor (AAC, ACSR, AAAC)

- Medium Voltage Cable, Low Voltage Cable

- Aerial Twisted Cable

- Junction And End Boxes

- Angled And Straight Separable Connector

- Public Lighting

- Manually Operated Aerial Switch (IACM)

- Generator

- Onduleur

- MV Mobile Transformer Station

- Prefabricated Metal Transformer Substation

- HTA Mobile Transformer Station

- MV/LV Transformer Substation

- Voltage Regulator

- Rectifier (Battery Charger)

- Low Voltage Panel

MV/LV Transformer Substation

The MV/LV substation, interface between the MV and LV distribution networks, is at the heart of electrical power distribution, as close as possible to the uses of low voltage electrical energy.

Electricity Distributors and users are concerned about quality energy at the optimum cost (the cost being understood here as the full cost, including of course the initial investment, but also the costs of operation, upkeep, maintenance ). In addition to these legitimate requirements, the equipment used on the electrical distribution networks must offer upgrade capabilities throughout their lifespan (most often around 30 years).

The MV/LV substation is in this respect one of the essential components on which the efforts of users and manufacturers are focused in order to improve quality while keeping costs under control.

French manufacturers, aware of these expectations and their evolution, are concerned to provide appropriate responses to the different scenarios. The following communication is intended above all to provide a broad overview of the needs and solutions in this area.

Features of the MV/LV substation.

The MV/LV substation can be adapted to all operating modes and must therefore fulfill the following functions:

- Distribute power and protect LV feeders.

- Isolate the substation from the network in the event of a fault

- Manage the MV network in the event of a fault

- Manage the MV network and the substation by remote control

We can therefore categorize sets by the networks they are used on as well as by the functions they perform.

The choice of earth connection diagrams adapted to each context makes it possible to respond on a case-by-case basis to the possible consequences of electrical faults between phases and earth on the safety of persons and the continuity of service.

This choice affects:

- Material sizing;

- Coupling of transformers.

Depending on the desired goals, this choice is to be made among the following solutions:

- Insulated neutral;

- Direct neutral to earth;

- Neutral earthed by impedance;

- Neutral earthed by tuned reactance or coil

In LV, in order to limit the extent of the consequences of a fault, it may be interesting to split the network into homogeneous batches, each of them having an appropriate earth connection scheme (islanding).

While the weight of local regulations and customs remains significant in the case of MV/LV substations, international standardization, based on IEC publications, is becoming more and more essential in all countries.

In addition, the trend towards turnkey solutions (prefabricated substations) is confirmed day by day.

The table below mentions the main reference standards in this area:

– IEC 529 Degrees of protection provided by enclosures (IP code)

– IEC 695 Relative fire tests

– IEC 1000 Electromagnetic Compatibility (EMC)

– IEC 1330 Prefabricated high voltage/low voltage substations

MV switchgear

IEC 694 Common clauses for high voltage switchgear and controlgear standardsTransformateur MT/BT Appareillage BT

IEC 76 Power transformers (immersed type)

LV equipment

IEC 439-1 low voltage switchgear assembly; Series sets and sets derived from series

SPECIFIC STANDARDS

IEC 298 Metal-enclosed switchgear

IEC 726 Dry-type power transformers

The structure substations respond to the manual or remote-controlled network management function, they do not have a transformer.

Placed on the network, they house MV breaking devices used for:

- Split the arteries to facilitate the search for defects,

- Isolate sections to allow exploitation operations.

There are several types:

Star positions

They allow extensions from the artery in several directions which can be isolated from each other by switch-disconnectors.

Cut-off cabinets

Positioned on the arteries, they allow them to be cut into two parts.

In some cases, this function is associated with a bypass allowing an antenna feeder connected by plug-in sockets.

MV/LV substations fulfill the function of LV power distribution and LV outgoing protection. Teams of MV breaking devices, they provide manual or remote-controlled network management.

There are several types:

5.1.2.1 MV/LV substations on overhead networks

They are generally offered without MV switchgear, this function being performed upstream on the network. They are made up of a pole-mounted transformer and a LV box.

5.1.2.2 MV/LV substations on underground networks

Base stations

Like the previous one, they are generally offered without MV breaking equipment. They are made up of a transformer and a LV box. The assembly is one-piece and can be installed with or without specific civil engineering (cleaning slab, casing, etc.)

Posts in artery cut

They are made up of a transformer, a LV panel and generally two disconnect switches to operate the feeder and a fuse switch or circuit breaker to protect the transformer.

The assembly is most often grouped together in a prefabricated cabin.

The substations ensure the distribution of electrical energy between the different points of use of an industrial or tertiary installation requiring significant power.

There are several types:

MV/LV substations supplied from the public distribution network,

MV/LV substations supplied from the public distribution network and an independent energy source.

They consist of a transformer, a LV panel adapted to the specific constraints of the network: industrial process, operation, generally two disconnecting switches to operate the artery and a fuse switch or circuit breaker to protect the transformer and incoming of the possible autonomous source.

In addition: MV, LV metering, power source transfer automation.

The assembly is most often grouped together in a prefabricated cabin.

The equipment present on the distribution networks is mainly intended to allow modifications to the operating diagram. The need to modify the diagram can be linked to incident situations, in which one seeks to isolate a defective section, to maintenance operations, for which one reorganizes the network in order to maintain the supply of all the customers, or there is still a desire to optimize operation by load distribution. The switchgear is therefore always located at strategic points in the network, depending on the electrical diagram and the topology. It is the equipment that allows the operation of the network and, as such, it must meet a certain number of functions and security and availability criteria. Operations are infrequent – a few per year on average – and the stresses in service are more of the dielectric type and linked to aging than linked to high mechanical endurance. Transformer protection devices on underground networks almost never operate because the transformer failure rate is very low and there is no reason to cut off the power supply to customers outside of an incident situation.

The equipment present on overhead networks makes it possible to modify the structure of the tree network or to isolate a branch or a group of transformers. These are mainly switch-disconnectors, with air breaking or enclosed breaking depending on the performance required. The corresponding equipment is designed to be installed on poles or gantries, although sometimes equivalent functions are performed with “underground” type equipment installed on the ground.

The different types of equipment for overhead networks are presented in depth in topic 3 to which the interested reader can refer.

Substations connected to the underground network, whether MV/MV substations or MV/LV substations, generally include an MV switchboard consisting mainly of switch-disconnectors and switch-fuses.

These switchboards are divided into completely closed metal compartments which contain all the connections and devices. In these simple switchboards requiring little maintenance under normal operating conditions, it is not considered useful to make certain elements withdrawable. Also, the separation of the various compartments is carried out by disconnecting devices which are either designed to restore the continuity of the enclosures in the open position (rotary disconnectors for example), or protected by enclosures made of synthetic materials (switch-disconnector in SF6 for example).

Barring exceptions, the equipment used in substations connected to the underground network falls into one of the following two categories (according to IEC298): compartmentalized or block.

“Network connection” modular cell

1.Modular cells:

They are separately transportable units which can be interconnected on site by busbars. This design allows the creation of complete and scalable systems capable of responding to all types of MV distribution diagrams, both for public distribution needs and for industrial needs. The disconnectors and switch-disconnectors fitted to these assemblies include, by design, a partitioning function which makes these cubicles compartmentalized equipment.

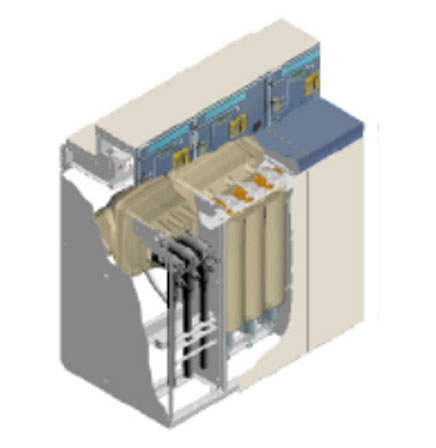

2.Compact or monoblock substations:

Most of the public distribution networks in urban areas are made in medium voltage loops operated open. This means that most MV switchboards consist of two (or even three) grid connection functions and one (or even two) transformer protection functions. Compact substations are therefore designed to meet this specific need with optimized characteristics.

In the field of switching and insulation techniques in medium voltage switchgear, the two original techniques (air and oil) have been gradually replaced by SF6. Air insulation is used in modular switchboards, but breaking is now exclusively in SF6. The use of SF6 allows both smaller dimensions and increased safety, with respect to the risk of fire.

Air-insulated switchgear (modular switchboards)

The corresponding tables comply with IEC298 which standardizes metal-enclosed switchgear. They are made up of functional units and divided into compartments that are completely closed on all sides, including the lower side of the envelope. Each compartment contains a set of connections or devices. There are usually two categories of compartments:

- Authorized access compartments in operation,

subject to de-energizing and grounding operations, which contain:

- cable connection devices, produced mainly by indoor single-pole ends, on this type of equipment.

- fuses

- circuit breakers

- current and voltage transformers for metering and/or protection.

Disconnectors are used exclusively in conjunction with functions

circuit breakers or in the “voltage transformer” functional units.

In current equipment, the switch functions also ensure circuit isolation and are therefore systematically switch-disconnectors. In the case of cubicles fitted with SF6 cut-off switches, the synthetic resin enclosure provides partitioning between the busbar and connection compartments.

- The access-prohibited compartments in operation, which are the busbar compartments. These compartments must only contain the busbar and any robust contacts that can be operated without load. It is forbidden to incorporate in these compartments devices requiring maintenance. These compartments are closed on all sides but are not partitioned between each functional unit (cell).

An optional low voltage box allows low voltage auxiliaries, measuring devices and relays to be installed on each cubicle. This compartment is accessible in normal operation.

Figure: monobloc single-tank switchboard with two switches and a transformer protection circuit breaker.

The examples of cells shown in Figures 1 and 2 meet most international standards, as well as some energy distributor specifications. Their design, of reduced width, allows their integration in cramped and difficult to access premises, or in prefabricated substations. They each comprise an SF6 switch-disconnector with a synthetic resin casing, supplemented if necessary by other equipment: fuses, measurement transformers, circuit breaker or SF6 contactor.

Figure: section of a transformer protection switch-fuse cubicle

They differ in the earthing switch function, which can be either in the SF6 and forming part of the switch-disconnector (figure 8, which illustrates a network connection function), or in the air and separated from the switch-disconnector (figure 9, which illustrates a transformer protection switch-fuse).

The performances of these categories of equipment make it possible to cover almost all the cases of medium voltage distribution networks.

Compact or monobloc devices with SF6 insulation

Figure: one-piece panel with juxtaposed functions with switch-fuse combination

The corresponding equipment also meets IEC298 for metal-enclosed switchgear. Their design is intended mainly for simple MV/LV substations on networks with an artery cut-off. They consist of a one-piece unit generally comprising 3 or 4 functions, switch-disconnectors for switching the network and protection for the transformer(s). Transformer protection can be offered by combined switch-fuses or by circuit breaker. The assembly is, a priori, non-extensible and transportable to the site of use in a single package, ready to be installed, fixed and connected.

All the necessary functions (including earthing switches) as well as the corresponding links (busbars and connections) are enclosed in a metal or metallized enclosure, filled with SF6 ensuring the two aspects of dielectric and breaking medium. This envelope is sealed for life (sealed pressure system, as defined in the IEC). Only the fuses, for access requirements in the event of replacement, are contained in separate compartments, insulated from the air and sealed. These compartments are only accessible when the corresponding switch is open and the earthing switches placed upstream and downstream are closed.

The connections of the various cables are made by directed field plug-in connectors, using 400 or 630 A bushings for the network cables and 50 or 200 A for the transformer outgoing cables.

Such a compact and directed-field design ensures the total absence of an electric field line in the ambient air and gives this type of equipment total insensitivity to environmental conditions, as well as the ability to withstand accidental immersion in service. Means of electrical access to the conductors of the network make it possible to carry out fault finding operations or dielectric verification of the cables.

Others products

Low Voltage Panel

Rectifier (Battery Charger)

Voltage Regulator